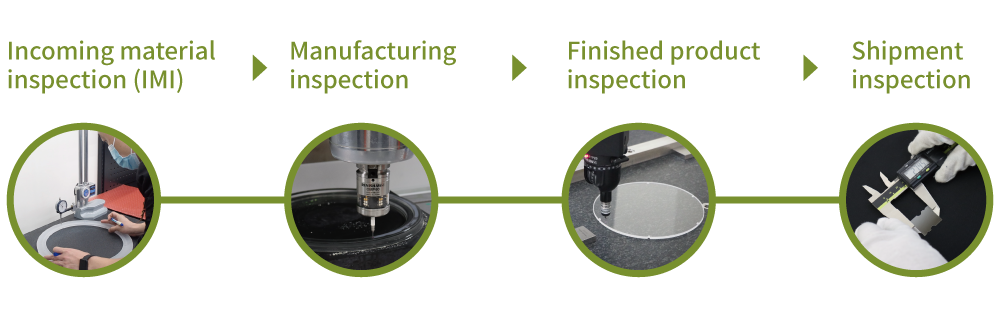

Quality management and control procedure

1Incoming quality control (IQC)

All raw materials entering the factory are inspected before they can be used in processing. Quality management of raw materials from suppliers is further enhanced in order to prevent substandard raw materials from being used and to ensure product quality.

2In process quailty control (IPQC)

Rigorous controls by performing inspections during manufacturing processes. Immediate inspection during processing ensures that all manufacturing parameters utilized in processes are comprehensively recorded.

3Final quality control (FQC)

Once products are completed, inspections are performed according to the different quality standards and requirements of final products. When verifying product specifications, substandard test results will result in the review of processing procedures and manufacturing parameters; arrangements will be made to rework/re-manufacture products so that they meet customer's specification requirements.

4Out-going quality control (OQC)

Our quality assurance team inspects all final products in the warehouse before they are packaged and loaded for shipping. Final inspections are performed to ensure that only the most appropriate products are delivered into the hands of our customers.